Induction sealing is the process of bonding thermoplastic materials by induction heating. This involves controlled heating an electrically conducting object (usually aluminium foil) by electromagnetic induction, through heat generated in the object by eddy currents.

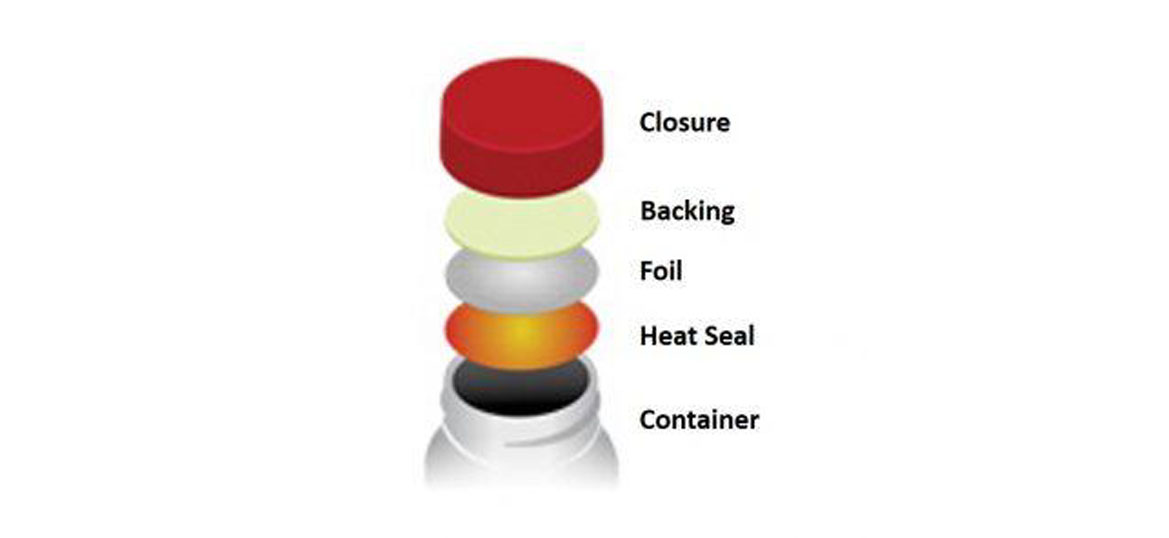

Induction seals play an important role when it comes to a product’s packaging. Induction sealing creates a hermetic seal through a closure that is lined with a heat-seal foil cover. The hermetic seal ensures the package is airtight and preserves the materials by keeping any contaminants from entering.

This type of sealing is used across many industries including pharmaceutical, nutraceutical, automotive, food and beverage, as well as health and beauty. Induction seals can be used in any industry that has a jar or bottle involved.

The Benefits of Using Induction Seals:

The use of induction seals offers numerous benefits to companies that use this type of sealing on their products’ packaging. First and foremost, induction seals provide tamper evidence. Because there is a heat seal that offers a layer of protection, the seal provides a secure seal that allows tampering to easily be identified.

Secondly, they preserve the contents inside the packaging by preventing oxygen and moisture from entering the package. This extends a product's shelf life and quality from production to consumption or use.

As mentioned previously, another benefit of using induction seals is the prevention of leaks with packages that contain a liquid content. The seal provides extra strength and security to the package’s opening to prevent leaking whether it is being shipped or transported from the store to a consumer’s home.

A) Electromagnetic Induction Capper

| Model | SPIS-100 |

|---|---|

| Voltage (V/Hz) | AC 220/50 |

| Power (W) | 500 |

| Heal diameter(mm) | 20-135 |

| Delivering speed | N/A |

| Vessel height | Absoluteness |

| Dimension(LxWXH) | 340x290x150 |

| Weight(kg) | 5 |

| Capacity | 0-100 pc./min |

B) Continuous Electromagnetic Induction Capper Continuous Electromagnetic induction capper is basically appropriate of capping operation of non- metal bottleneck like glass and plastics. It is applicable specifically for those customers who need continuous capping operation with huge output. This machine is mostly applicable for capping operation of high threaded cap.

Table Top Electromagnetic induction capper is most applicable for capping operation of flat-capped small bottleneck with thread that is fabricated of non-metal materials such as glass, plastic while it is not apt for metal & non-threaded bottleneck, or bottleneck, or seamful high cap, whose diameter is ranging 20-135. Especially, our capper is fit for the patron who carrying out continuous capping operation for large output and lot.

| Model | SPIS-200C |

|---|---|

| Voltage (V/Hz) | 220V/50 |

| Power (W) | 1.5KW |

| Heal diameter(mm) | 20-135 |

| Delivering speed | 20-135 |

| Vessel height | 0-10 mt/mint. |

| Dimension(LxWXH) | 1150x480x400 |

| Weight(kg) | 45kg |

| Capacity | 150pc./mint(with diameter 100mm,flat capped and PE bottle) |